Why Useful Hard Surface Piercing Methods Are Practical For Builders

Modern builds and remodels call for openings in tough materials. A slab may need a trench for drains, a wall may need a new doorway, and a mechanical room may need dozens of penetrations.

Brute-force breaking can work, though it can leave rough edges that slow the next trade.

Hard Surfaces On Site Are Tough For A Reason

Concrete, masonry, stone, and asphalt are built to resist wear, water, and load. That strength is great for the finished project, though it makes late changes harder. Rebar, mesh, and embedded conduit can turn a simple opening into a careful operation.

Hard surface piercing is the controlled removal of material by cutting, sawing, drilling, or coring. Diamond blades and diamond bits grind rather than strike, so the work can follow a layout line with tight tolerances. The result is a crisp opening that needs less repair around the edges.

Tool choices matter, since each method fits a different geometry. Slab saws handle long floor cuts, wall saws track clean vertical lines, and core drills make round holes with smooth sides. For thick sections, wire sawing reaches spots standard blades miss.

Cleaner Openings Mean Cleaner Schedules

A clean opening saves time on patching and layout changes. When the work calls for accurate penetrations, crews often coordinate with concrete cutting and coring contractors to hit exact dimensions and keep other trades moving. That control cuts down rework and keeps inspections simple.

Precision openings support better sequencing on busy sites. A saw-cut trench can be backfilled sooner than a jagged jackhammer channel, and the surrounding slab is easier to finish. The job stays calmer when debris is smaller, cleanup is faster, and the work area stays defined.

Dust Control And Silica Limits Shape The Plan

Cutting and drilling can release fine dust that travels far past the work zone. When concrete contains crystalline silica, that dust can raise health risks and trigger strict rules.

CDC’s NIOSH guidance highlights an OSHA permissible exposure limit of 50 µg/m³ as an 8-hour time-weighted average, which sets a clear bar for job planning.

Practical controls start with the method itself. Wet cutting, shrouds, and HEPA vacuums can capture dust at the source, and barriers can keep the rest of the floor cleaner. Good planning covers slurry management, floor protection, and a cleanup routine that avoids dry sweeping.

Air monitoring and task timing show which controls work on that site. Training and fit-tested respirators can close gaps when engineering controls fall short.

Low-Vibration Options Protect Surrounding Work

Impact demolition sends vibration through the structure, and that movement can chip tile, crack plaster, or loosen anchors near the cut line.

Vibration can be a bigger concern near old concrete, delicate finishes, or active operations in the next room.

Piercing methods that remove material with steady abrasion reduce the chance of collateral damage. Wire sawing is one option used for large or awkward cuts where access is limited.

A wire sawing guide for big concrete elements notes that the process produces minimal vibration, which reduces the risk of weakening nearby areas and avoids damage to adjacent structures.

That makes it useful when the cut sits close to columns, bridge elements, or sensitive utilities.

Retrofits Need Precision, Not Guesswork

Renovation work rarely matches a perfect set of drawings. Existing conditions can shift, and new MEP routes may need last-minute adjustments. Piercing methods let crews place openings exactly where the updated layout requires, without turning a small change into a full tear-out.

Examples include work like the items below. These tasks show up in new work and renovations:

- Core holes for new plumbing stacks, sleeves, or anchor bolts

- Wall openings for doors, ducts, or service panels

- Slot cuts in slabs for conduit runs or floor boxes

- Removal cuts for equipment pads or housekeeping bases

- Test cores for strength checks or mix verification

Clean edges help the next step go faster, whether that step is setting a sleeve, installing a frame, or applying a firestop system. Neat geometry can reduce the size of patch areas, which keeps finish crews from chasing uneven surfaces.

Planning Details That Make Piercing Work Smooth

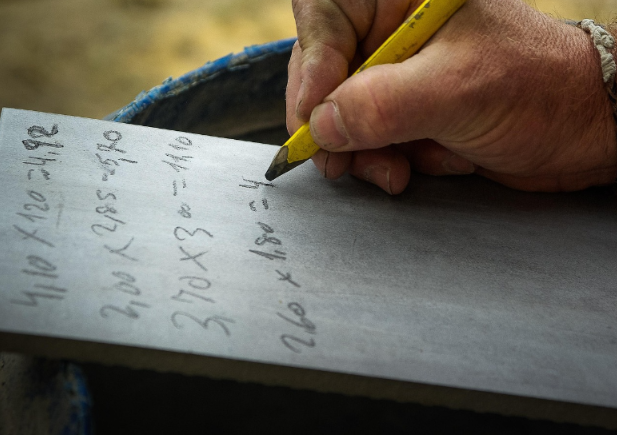

Good piercing work starts before the blade touches the surface. Field verification, rebar locating, and utility tracing reduce surprises, and clear markings keep the team aligned. Access, power, water supply, and noise controls should be part of the same plan.

The work area needs a strategy for slurry, spoil, and protection of nearby finishes. Lift points, fall protection, and confined space rules may apply to vertical cuts or deep cores.

A short pre-task check can cover blade selection, guarding, and the stop points that protect post-tension systems.

Piercing methods are practical for builders since they deliver controlled results in hard materials without the chaos of brute-force breaking. Clean openings support smoother schedules, and smart dust and vibration controls protect both people and the structure.

With the right plan, these methods turn tough concrete and masonry into manageable scopes that fit modern construction timelines.

We create powerful, insightful content that fuels the minds of entrepreneurs and business owners, inspiring them to innovate, grow, and succeed.