A safer workplace does not happen by accident. It takes clear goals, steady habits, and a plan that fits how your teams actually work. Use the ideas below to build momentum, lower risks, and keep people healthy on the job.

Know the Numbers to Focus Your Efforts

Start with facts and target the right problems head-on. Recent figures from the Bureau of Labor Statistics show private employers recorded 2.5 million nonfatal injuries and illnesses in 2024, a small but real drop from the year before. That trend still represents millions of painful events that companies can prevent with better planning.

Turn those figures into action by mapping your top three incident types, locations, and shifts. If sprains spike in receiving or cuts rise on the night shift, you know where to start. Post simple dashboards and review them in weekly huddles so fixes do not get lost.

Build a Safety Culture That Actually Sticks

Culture is what people do when no one is watching. Leaders model safe behavior, inviting near-miss reports, and praising fixes that remove hazards. New hires should learn the same rules from day one, and long-time employees should be part of rewriting any rule that does not fit reality.

Everyone has a role in safety, from managers to new hires. If a serious injury happens, understand your rights and options and hire personal injury legal support that can help workers and families go through the aftermath. It’s a reminder that motivates leaders to invest in prevention.

Use Data and Report the Right Way

In a recent update, OSHA said it received hundreds of thousands of annual summaries and posted partial data from more than 700,000 detailed injury and illness forms. That volume of information helps employers spot patterns and benchmark performance.

Use your Form 300, 300A, and 301 entries to track root causes, not just body parts and days away. Group similar events and ask what condition allowed them to occur. Set quarterly goals that remove specific hazards, like replacing a tool, adding a guard, or changing a procedure.

Target the Highest Costs With Smart Controls

Injuries carry large price tags in medical bills, lost time, and productivity. The National Safety Council estimates the total cost of work injuries topped $176.5 billion in 2023, which is a strong case for spending early on prevention.

Put your money where it cuts the most risk. Focus on controls that change the workplace, not only worker behavior. For quick wins, try a mix of the ideas below and track results for 90 days:

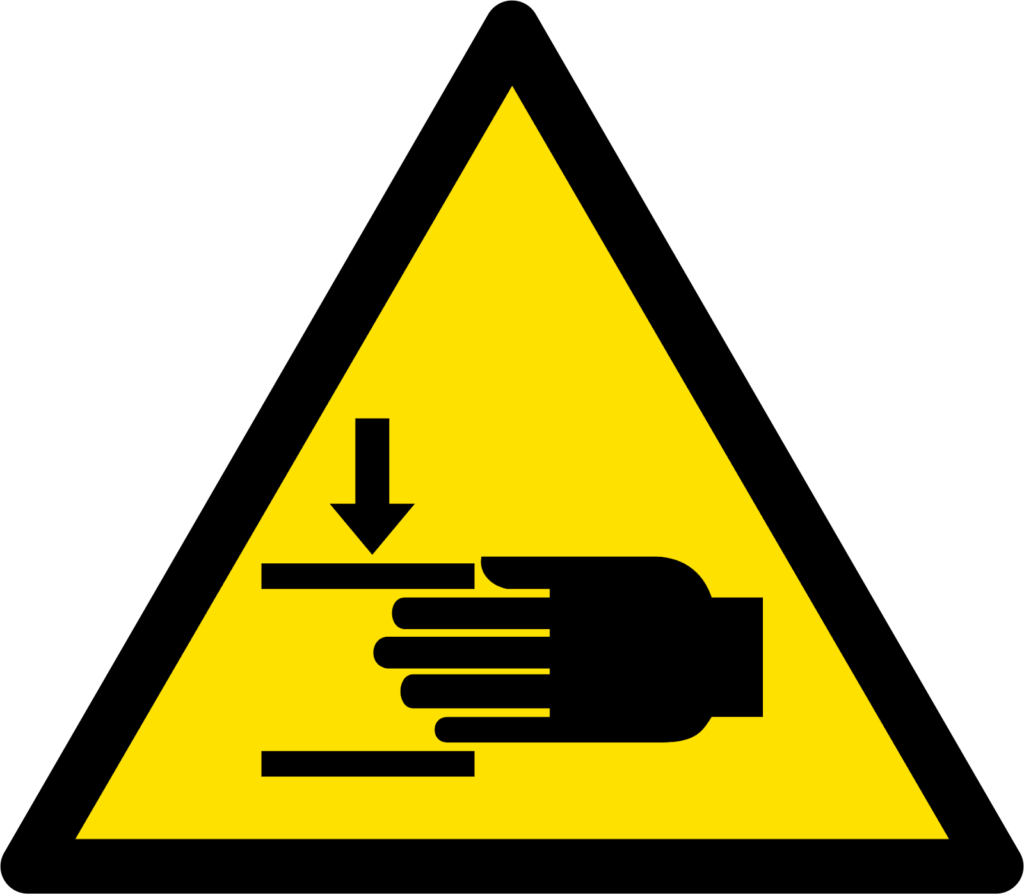

- Install physical guards or interlocks on high-risk equipment

- Redesign storage to reduce heavy lifts and awkward reaches

- Standardize tools, PPE, and labeling across similar tasks

- Add visual cues like floor markings and shadow boards

- Pilot job rotation where exposure builds over long shifts

Prepare for Heat, Cold, and Weather Risks

Climate and seasons raise unique risks that standard rules might miss. The Labor Department has reported thousands of federal heat inspections since launching a focused program, which shows how often workers face dangerous temperatures. Treat heat like any other hazard with controls and training.

Build a simple plan before summer. Provide cool water, shade, and rest breaks on a set schedule. Train supervisors to recognize heat illness fast. Use buddy checks on the hottest days and move heavy work to earlier hours when you can. In colder months, plan for warm-up breaks and dry gear.

Train, Practice, and Improve Continuously

Short, frequent training beats long classes once a year. Keep lessons practical, hands-on, and tied to recent incidents. Use toolbox talks to review one control at a time, then watch teams try it in real conditions and offer coaching on the spot.

Practice emergency responses the same way. Run drills for machine lockout, fire, weather shelter, and first aid. After each drill, ask what went well, what slowed people down, and what equipment or signage needs to change. Update your procedures the same day while details are fresh.

Make Reporting Easy and Act On It Fast

People will speak up if it is simple and safe to do so. Offer multiple ways to report hazards and near misses, like a QR code, a short form, or a hotline. Promise quick feedback and prove it by closing the loop within a week, even if the final fix takes longer.

Thank the person, share the plan, and post before-and-after photos where the change happened. When employees see their input become real improvements, they will keep the ideas coming.

No program is perfect, but steady progress builds real protection. Keep removing hazards, keep listening to workers, and keep measuring what matters. Safer work today means healthier people and stronger teams tomorrow.

We create powerful, insightful content that fuels the minds of entrepreneurs and business owners, inspiring them to innovate, grow, and succeed.